PolyMide PA6-CF 1.75mm 500g Black, Polymaker

Indicated wieght: actual amount of printable material.

54,99 € VAT exc.

PolyMide™ is a family of Nylon/polyamide based filaments. Produced with Polymaker’s Warp-Free™ technology, PolyMide™ filaments deliver engineering properties intrinsic to Nylon and ease of printing.

PolyMide™ PA6-CF is a carbon fiber reinforced PA6 (Nylon 6) filament. The carbon fiber reinforcement provides significantly improved stiffness, strength and heat resistance with outstanding layer adhesion.

| Recommended settings | Mechanical properties | Thermal properties | Notes |

| Nozzle Temperature: 280˚C – 300˚C |

Young’s Modulus: 7453 ± 656 (MPa) |

Heat Deflection Temperature (ISO 75 1.8 MPa): 196 ˚C |

Drying Settings: 80˚C for 12h |

| Printing Speed: 60mm/s |

Tensile Strength: 105.0 ± 5.0 (MPa) |

Heat Deflection Temperature (ISO 75 0.45 MPa): 215 ˚C |

Recommended Support Materials: BVOH |

| Bed Temperature: 25˚C – 50˚C (Do NOT exceed 50 ˚C) |

Bending Strength: 169.0 ± 4.7 (MPa) |

Melting Temperature: 220 (°C) |

Other: Annealing 80℃ 6h |

| Bed Surface: almost any surface with a thin coat of 3DLac |

Charpy Impact Strength: 13.34 ± 0.52 (kJ/m2) |

||

| Cooling Fan: OFF |

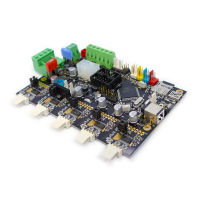

We highly recommend to use a wear resistant nozzle

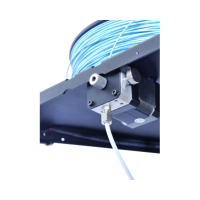

PolyMide™ PA6 CF features Polymaker's Warp-Free™ technology and Fiber Adhesion™ technology:

Warp-Free™ technology enables the production of Nylon-based filaments that can be 3D printed with excellent dimensional stability and near-zero warpage. This is achieved by the fine control of microstructure and crystallization behavior of Nylon, which enables the material to fully release the internal stress before solidification.